Roll-to-Roll Manufacturing Advances Mass Production of Stretchable Electronics

Scientists are using roll-to-roll manufacturing methods to produce stretchable electronics in large quantities, aiming to transform the medical device sector with flexible, robust, and economical solutions.

Roll-to-Roll Manufacturing for Stretchable Electronics

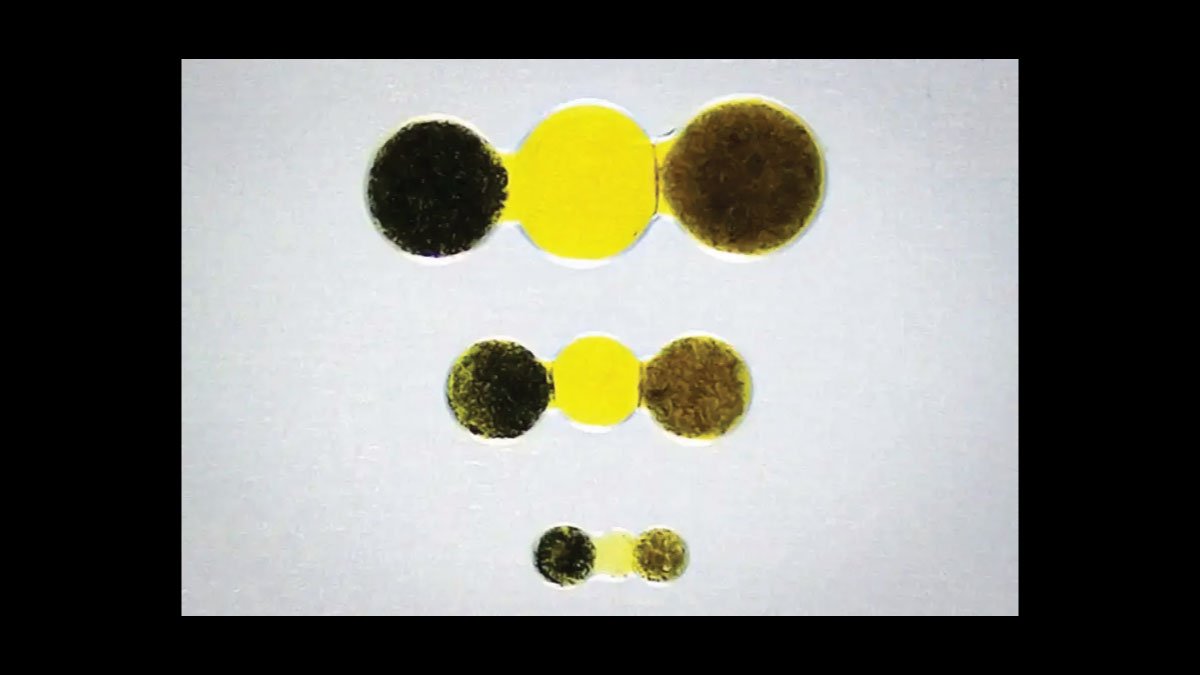

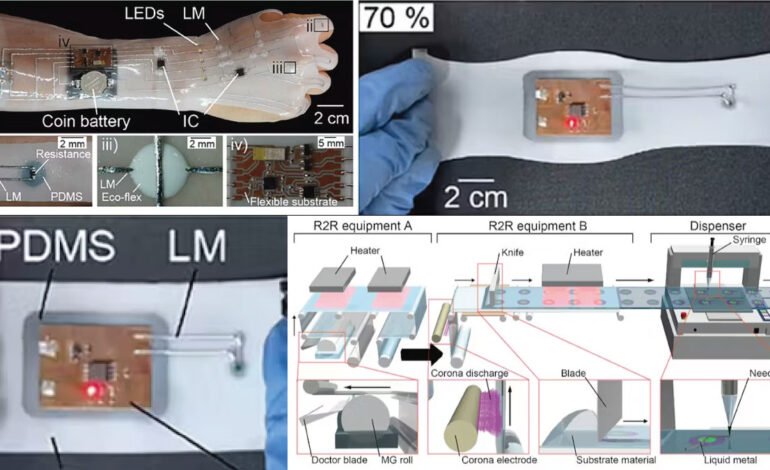

The development of stretchable electronics has been a major area of focus in cutting-edge manufacturing, particularly in the healthcare sector. Now, researchers from Yokohama National University and other leading institutions are turning to roll-to-roll (R2R) manufacturing to increase the production of these innovative devices. This technique, which is commonly used in printing, involves continuously passing a flexible substrate through rollers, allowing for high-speed and large-scale production.

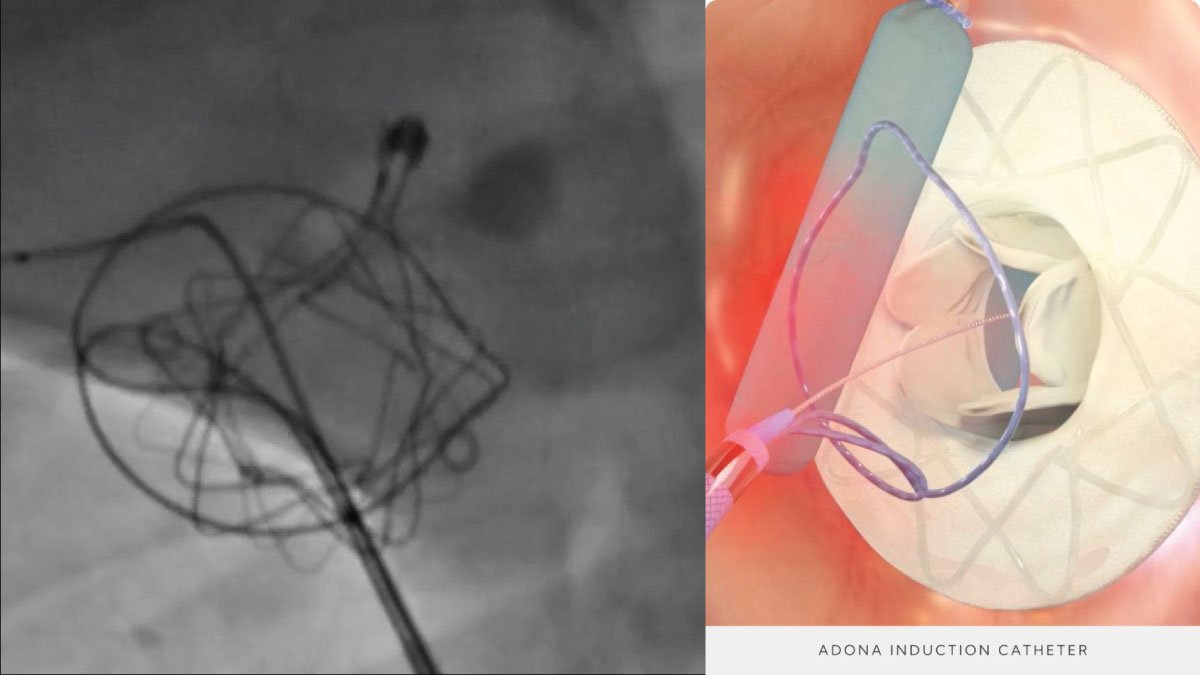

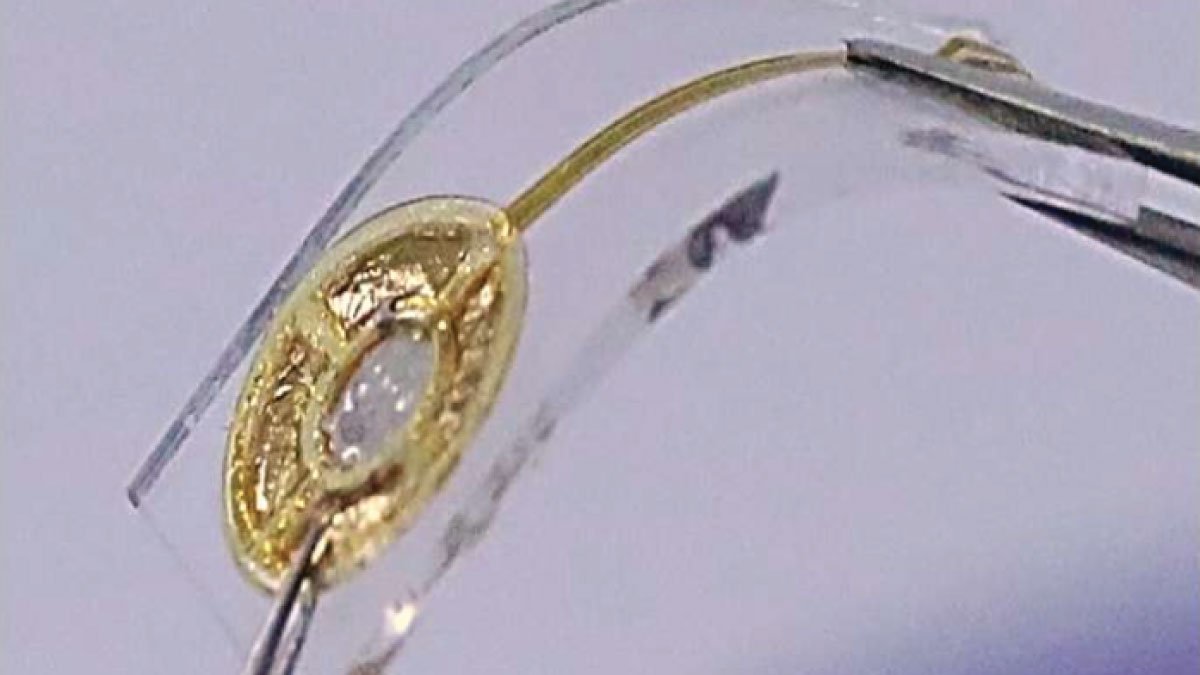

R2R manufacturing offers a revolutionary chance to produce stretchable electronics more efficiently and affordably than ever before. This is essential for applications that require materials to conform to intricate surfaces, such as wearable health monitors, implantable medical devices, and stretchable sensors.

Advantages of Roll-to-roll manufacturing

The implementation of R2R manufacturing brings several significant benefits. Firstly, the continuous production process of stretchable electronics significantly reduces both the cost and time required for manufacturing. This efficiency is especially valuable in the medical field, where there is a growing demand for flexible, durable, and lightweight devices.

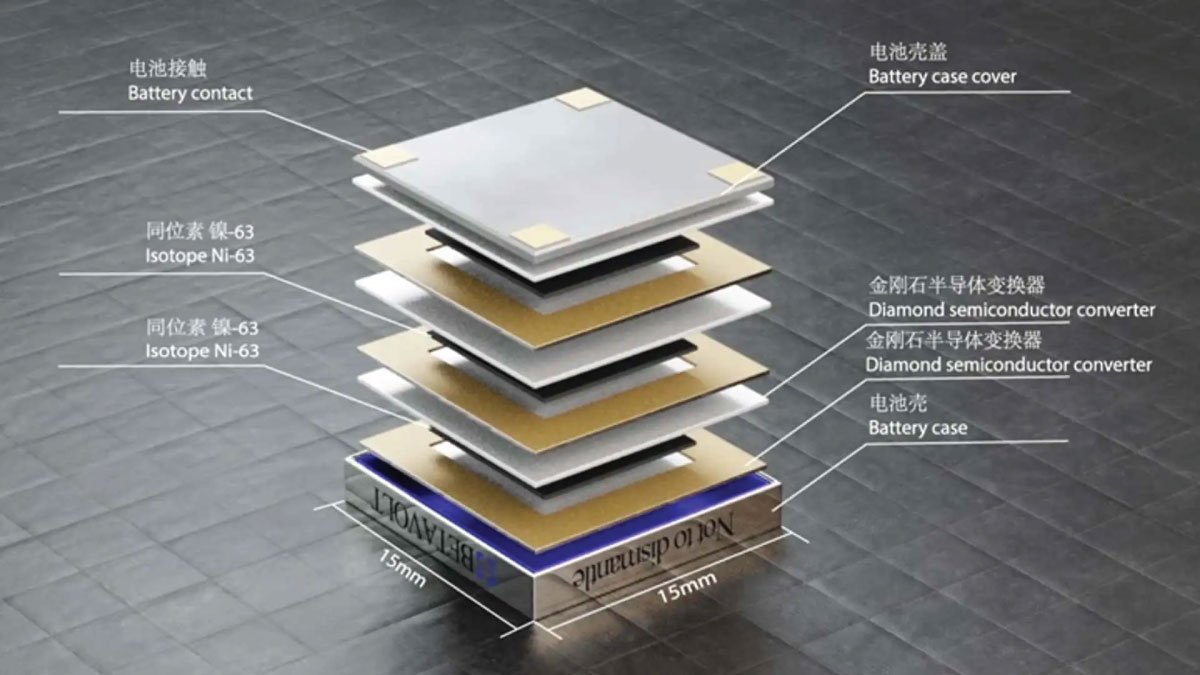

Secondly, Roll-to-roll manufacturing supports the use of a broad spectrum of materials, including polymers, metals, and semiconductors, allowing for the creation of multifunctional devices. This versatility enables manufacturers to tailor the electronic properties of these devices to meet specific medical needs, such as biocompatibility, conductivity, and stretchability.

Furthermore, the scalability of Roll-to-roll manufacturing makes it the perfect solution for meeting the rising demand for stretchable electronics in the medical device industry. As more applications emerge, including smart bandages, flexible biosensors, and stretchable drug delivery systems, the need to produce these devices in large quantities becomes increasingly critical.

Future Trends in Stretchable Electronics

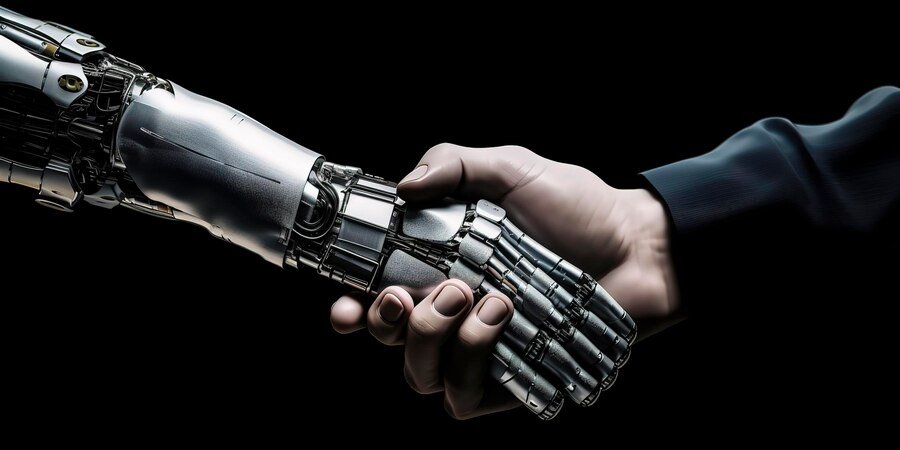

The transition towards roll-to-roll manufacturing marks a significant milestone in the advancement of stretchable electronics. Looking ahead, we can anticipate further progress in the integration of these devices with other emerging technologies, such as artificial intelligence and wireless communication systems. This could lead to the creation of smart, interconnected medical devices that provide real-time monitoring and data analysis, improving patient care and outcomes.

Moreover, as researchers refine the roll-to-roll process, we may witness the introduction of even more complex and high-performance stretchable electronics into the market. These advancements will likely broaden the scope of medical applications, from wearable health technology to advanced prosthetics and more.

Conclusion

The adoption of roll-to-roll manufacturing for the mass production of stretchable electronics represents a significant step forward in the technology of medical devices. With its capacity to produce flexible, durable, and cost-effective solutions on a large scale, R2R manufacturing is set to play a crucial role in the future of healthcare. As this technology continues to evolve, it will undoubtedly open new avenues for innovation in medical devices, enhancing the quality of care for patients around the globe.